The integrated thermal insulation and decoration board has many advantages and is currently included in the Guiding Catalogue of Industrial Structure Adjustment (2019 Draft). The thermal insulation materials incorporated include rock wool, aerogel, vacuum thermal insulation board, interior thermal insulation decorative integrated board and other thermal insulation materials. This paper summarizes the common practices of its nodes.

Node processing description:

(1) Node treatment is an important part of quality assurance, which should be properly handled in combination with the actual construction experience and specifications and standards. The following nodes are drawn according to the specification and belong to the general node processing method. During the actual construction, the detailed design shall be made according to the site and drawings in order to adapt to local conditions and be scientific and reasonable.

(2) Each node is a complete construction process, and the main node structure is an important supplement to the construction process;

(3) The external doors and windows are basically free of thermal bridge, while the middle doors and windows need to be insulated at the side of the door and window openings;

(4) The nodes of door and window openings and internal and external corner nodes are basic nodes, and nodes of other parts are formed on this basis. For example, the convex window is actually a combination of internal and external corner and door and window opening nodes, and the practices of parapet, deformation joint and plinth are also part of it. The practices of through wall pipes and rainwater downpipes only add the opening process of thermal insulation decorative plates, and other practices are consistent.

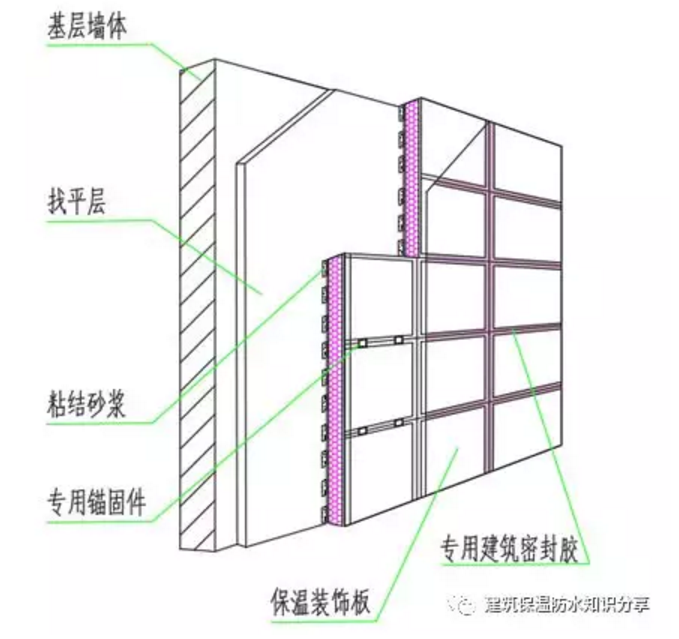

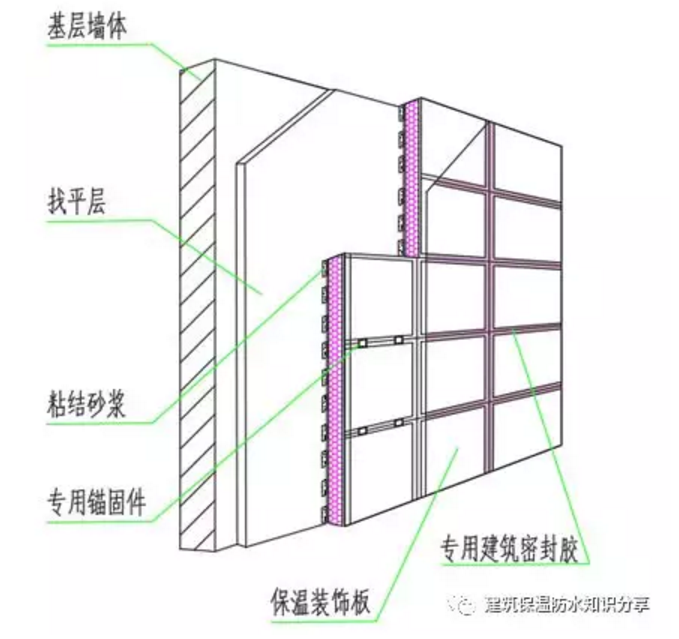

1. General structure diagram

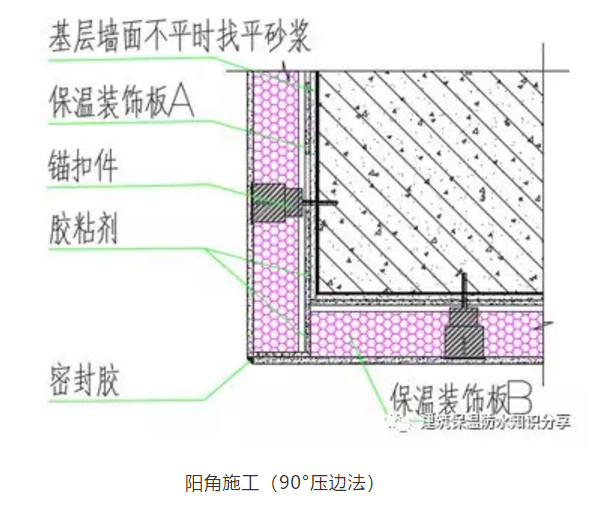

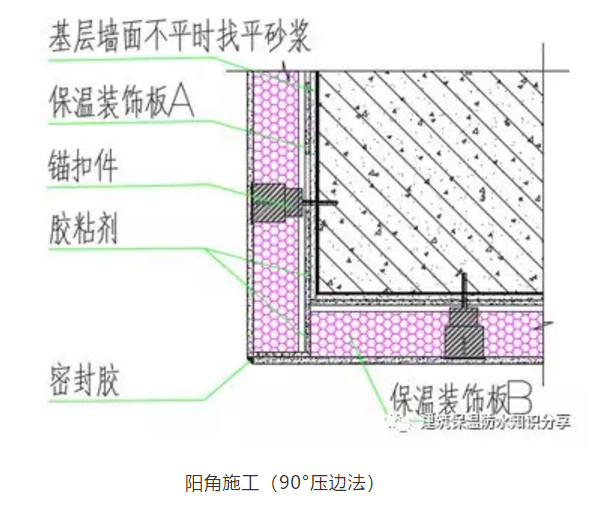

2. External corner node

(1) Although there are several combinations of external corners (45/90), the 90 ° blank holder method is widely used because of its small construction difficulty;

(2) For the thermal insulation decorative plate to be treated, only use machines and tools to remove the edge thermal insulation materials, and the removed parts should be accurate in size and angle;

(3) With the 90 ° blank holder method, first install the decorative plate A without removing part of the thermal insulation materials, and then install the thermal insulation decorative plate B with removing part of the thermal insulation materials;

(4) The thermal insulation decorative plate at the external corner shall be fully adhered within 200mm from the wall corner;

(5) When pasting the thermal insulation decorative plate installed later, the joint with the thermal insulation decorative plate on the other side should be coated with adhesive, and the coating amount should not leave a gap;

(6) The insulation decorative plate shall contact the bottom of the insulation decorative panel, and the insulation material shall not be exposed;

(7) The thermal insulation decorative plate shall be fixed up and down, and the distance from the anchor to the edge of the wall corner shall not be more than 200mm. The side anchor of the thermal insulation decorative plate can be set according to the situation;

(8) Sealant shall be used to seal the top corners of the insulation decorative plates on both sides;

(9) L-shaped finished thermal insulation decorative boards can also be used at the external corners, but the requirements for the flatness of the base course are very high.

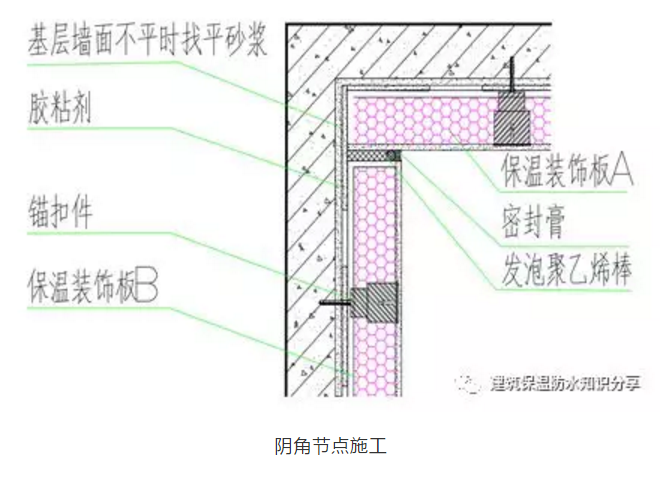

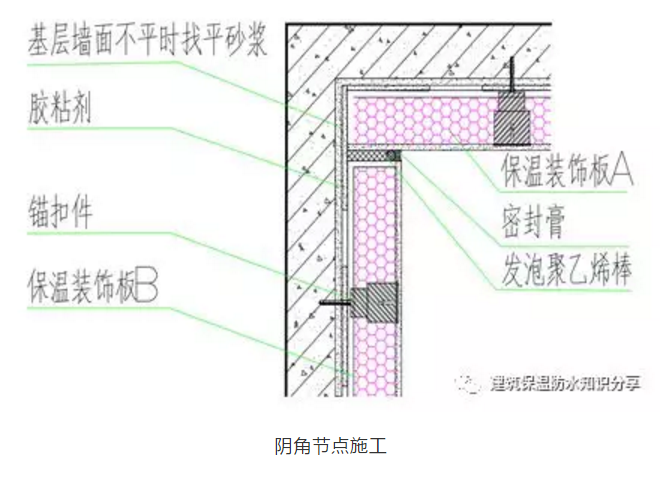

3. Internal corner node

(1) The two pieces of insulation decoration at the internal corner shall be installed by overlapping method;

(2) The gap width of the insulation decorative plates on both sides should be 5-8mm;

(3) The bonding area ratio shall be appropriately increased at the internal corner, and the thermal insulation decorative plate shall be fixed up and down;

(4) The side anchor of the thermal insulation decorative plate can be set according to the situation;

(5) The gaps between the insulation decorative plates on both sides shall be filled with caulking materials, and then sealed with silicone sealant;

(6) L-shaped finished thermal insulation decorative boards can also be used at the internal corners. However, because the perpendicularity of the wall at the construction site is not easy to meet the requirements, 90 ° blank holder is often used.

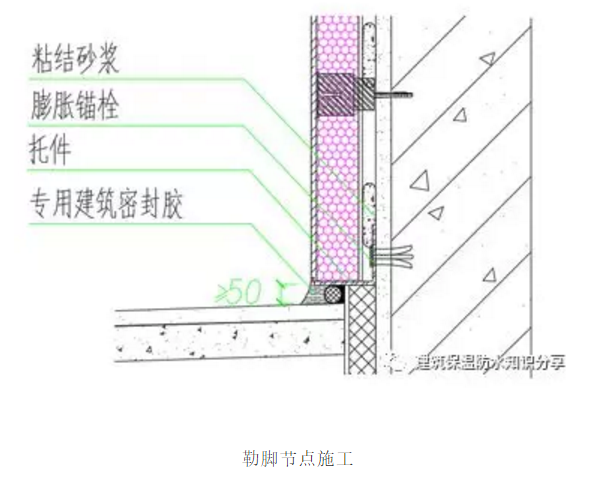

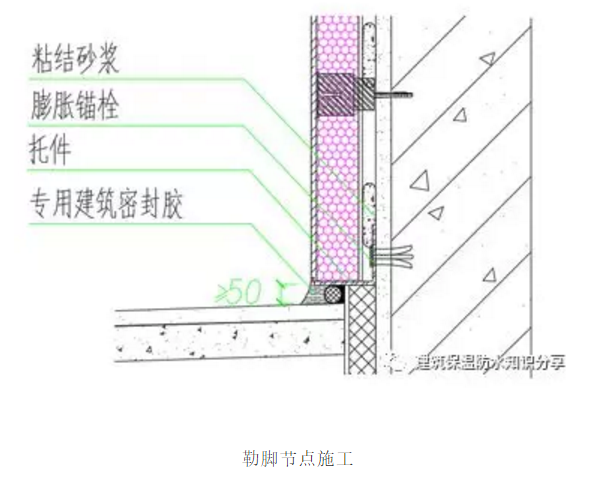

4. Plinth node

(1) The thermal insulation decorative plate shall be installed first, and then the apron shall be made as required;

(2) The lower end of the bottom insulation decorative plate shall be provided with a bracket, and the distance between the lower edge of the insulation decorative plate and the base course shall not be less than 50mm;

(3) The sticking area ratio of the bottom insulation decorative board shall be increased appropriately;

(4) The joint between apron and insulation decorative plate shall be sealed with sealant, and there shall be a gap of not less than 20mm at the joint.

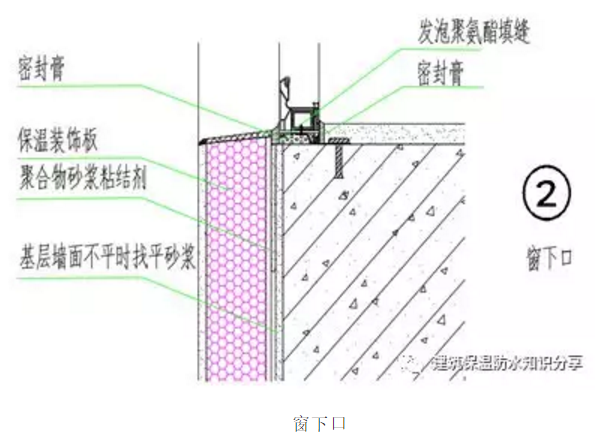

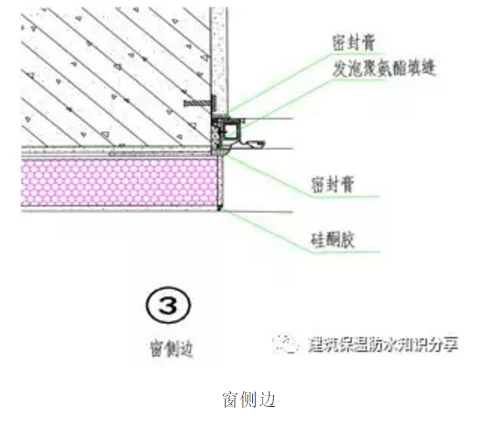

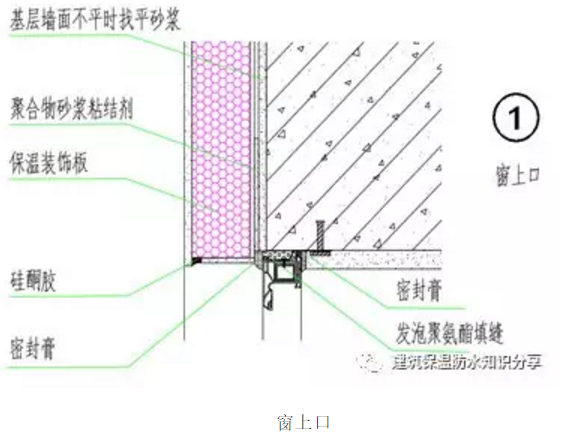

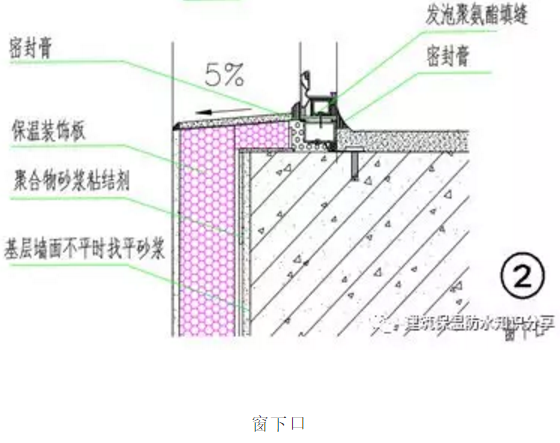

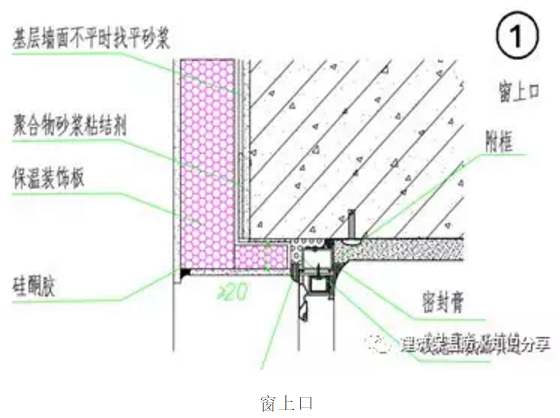

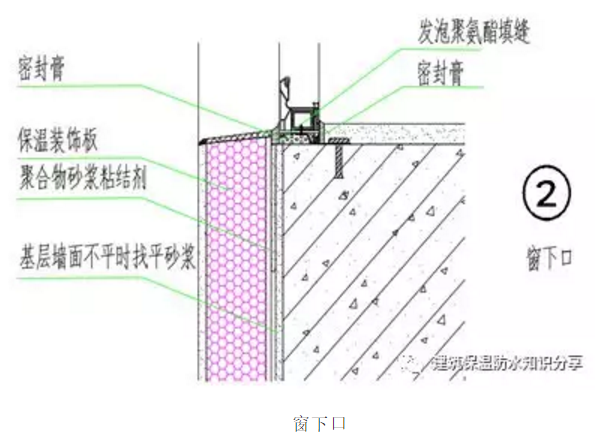

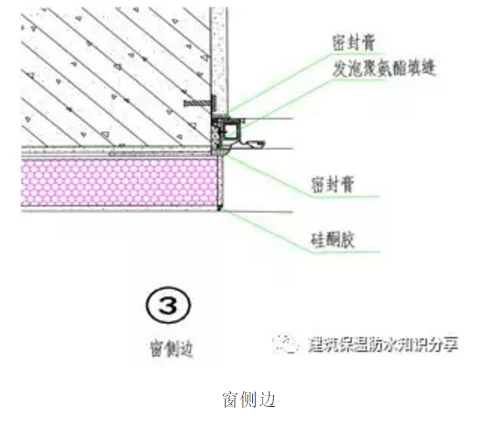

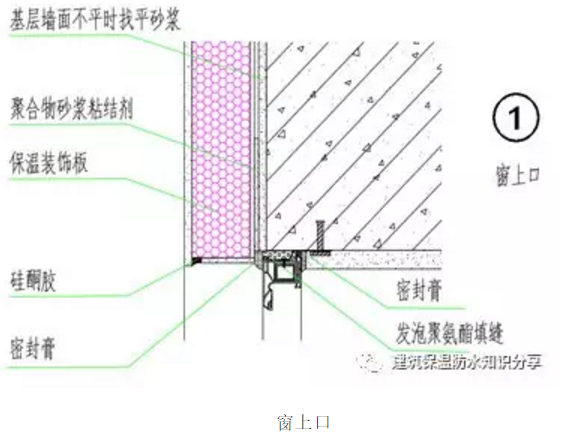

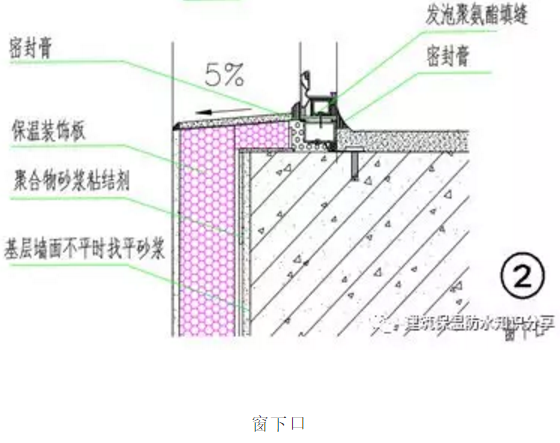

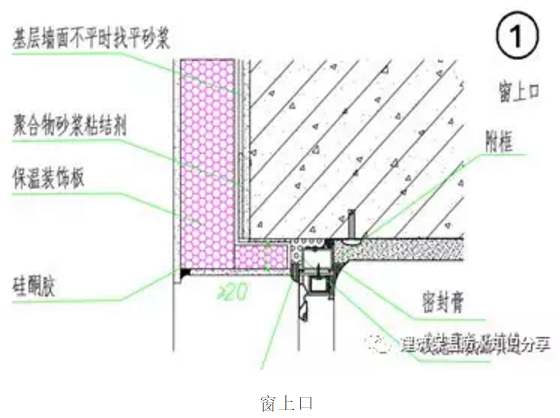

5. Nodes at the opening of external doors and windows (flush hung windows)

(1) The bonding area ratio of the wall insulation decorative plate at the external door and window openings shall be appropriately increased, and the wall insulation decorative plate shall extend out of the outer wall edge appropriately;

(2) The thermal insulation decorative plates on the door and window tops and window sills shall be fixed left and right, and the thermal insulation decorative plates on the walls at both sides of the door and window shall be fixed up and down. The length of the anchor from the edge of the wall corner shall not be less than 200mm. Other anchors of wall insulation decorative plate can be set according to the situation;

(3) The side of the thermal insulation decorative plate shall be pasted with decorative panels of the same material. The decorative panels shall be fully pasted. The decorative panels of the door and window tops and window sills shall form a downward slope of not less than 5%;

(4) The thermal insulation decorative panel shall contact the bottom of the wall thermal insulation decorative panel, the thermal insulation material shall not be exposed, and the gap between the decorative panel and the door and window frame shall be 5mm~8mm;

(5) The gap between the decorative panel and the window frame and the top corner of the wall insulation decorative panel shall be sealed with sealant.

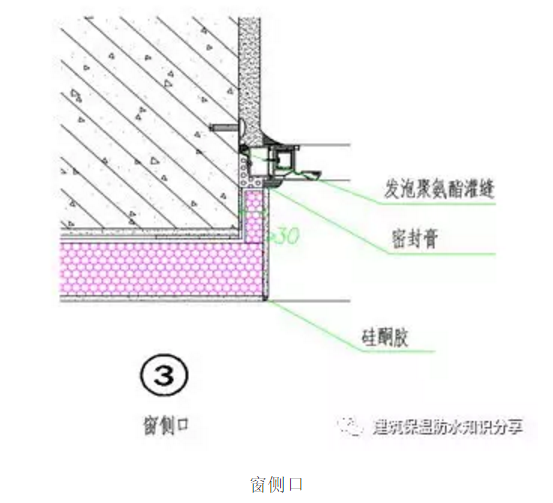

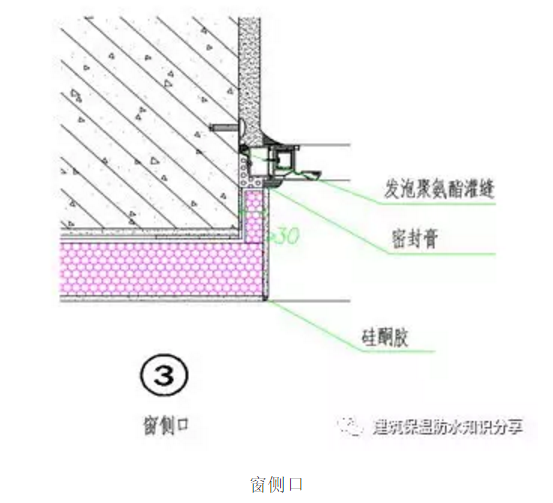

6. Node at the middle door and window opening

(1) The sides of the wall around the middle door and window openings shall be installed with thermal insulation decorative plates, and the thermal insulation materials shall not be less than 20mm;

(2) The thermal insulation decorative plate can be installed by 90 ° blank pressing method or 45 ° diagonal method, and the wall insulation decorative plate shall be installed first, then the side decorative plate;

(3) The sticking area ratio of wall thermal insulation decorative plates at the middle door and window openings shall be appropriately increased. The thermal insulation decorative plates on the door and window tops and window sills shall be fixed left and right, and the thermal insulation decorative plates on both sides of the doors and windows shall be fixed up and down. The distance between the anchor and the edge of the wall corner shall not be more than 200mm. The anchor of wall thermal insulation decorative plates and other sides can be set according to the situation;

(4) The side thermal insulation decorative plate shall be fully adhered. The thermal insulation decorative plate at the top of the door and window and the side of the window sill shall form a downward slope of not less than 5%. The side thermal insulation decorative plate shall contact the bottom of the wall thermal insulation decorative plate. The thermal insulation material shall not be exposed. The gap between the side thermal insulation decorative plate and the door and window frame shall not be less than 5mm~8mm;

(5) The gap between the side insulation decorative plate and the door and window frame shall be filled with caulking material, and then sealed with sealant. The top corner of wall insulation decorative plate and side insulation decorative plate shall be sealed with sealant.

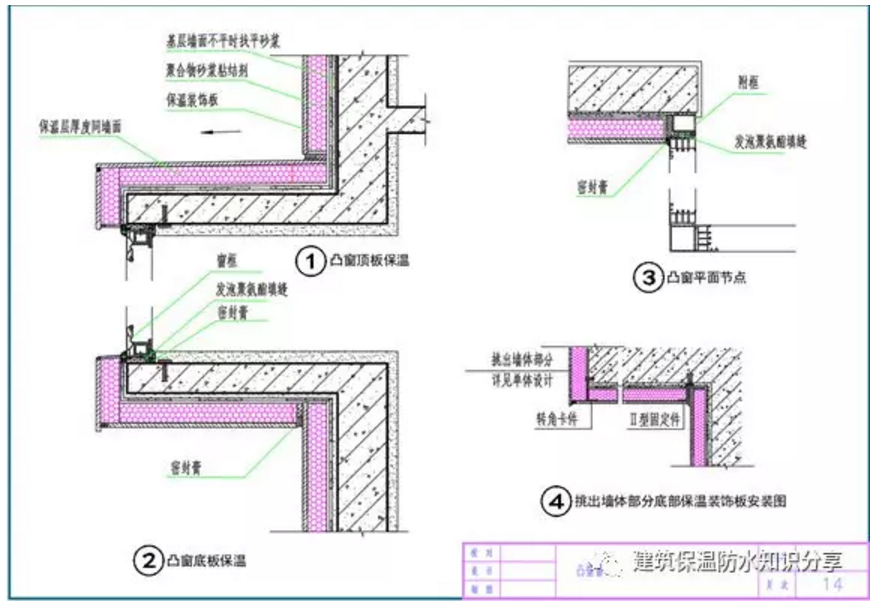

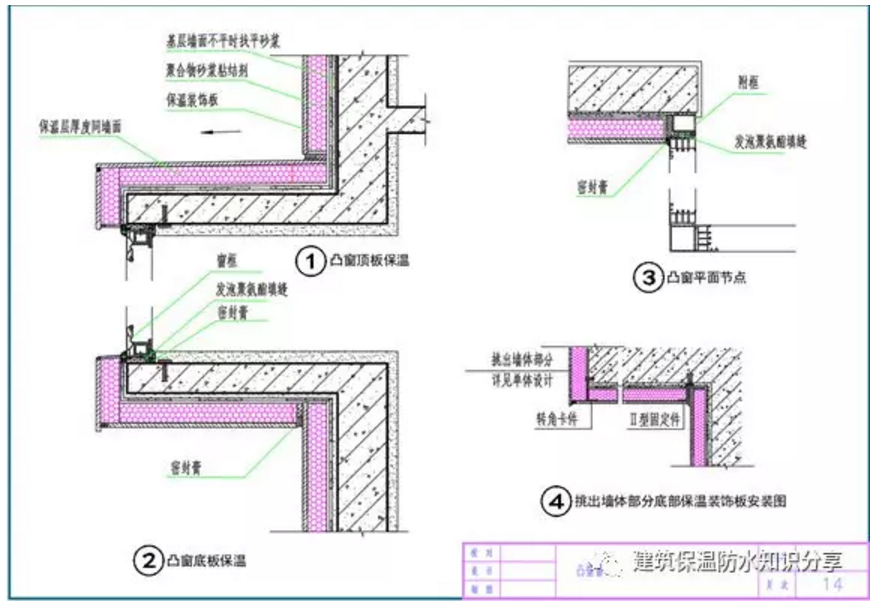

7. Node at bay window

(1) The construction shall be carried out according to the key points of external corners, internal corners and door and window openings;

(2) The lower bottom plate of bay window shall be pasted with thermal insulation decorative plate, and the bonding area ratio shall be appropriately increased. The width of thermal insulation decorative plate shall not be greater than 600mm;

(3) The upper part of the bay window shall be pasted with thermal insulation decorative plate;

(4) When the air conditioner outdoor unit is set at the top of the bay window, other insulation forms can be used.

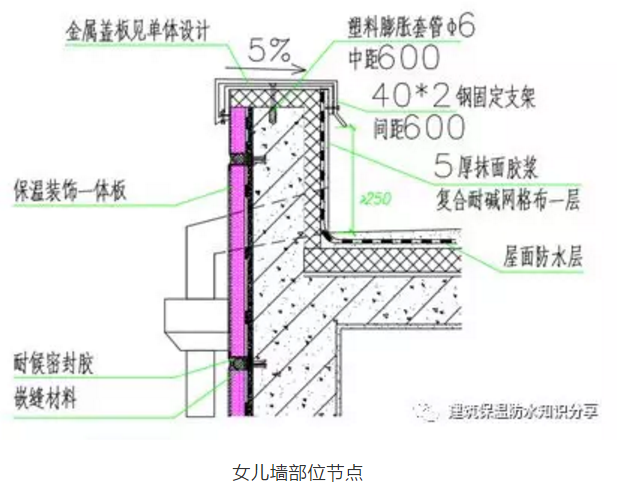

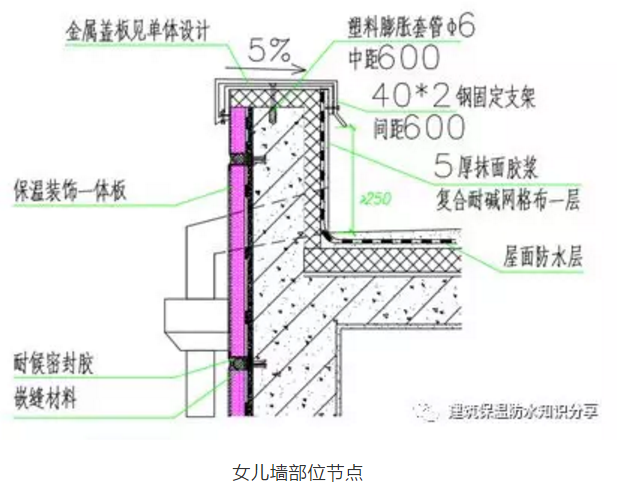

8. Parapet node

(1) The construction shall be carried out according to the key points of internal corners, external corners and bay windows;

(2) When pasting the insulation decorative plate at the lightning rod and other perforated parts, it shall be filled with adhesive and sealed with sealant;

(3) The top insulation decorative plate shall form a downward slope of not less than 5% towards the inside of the building.

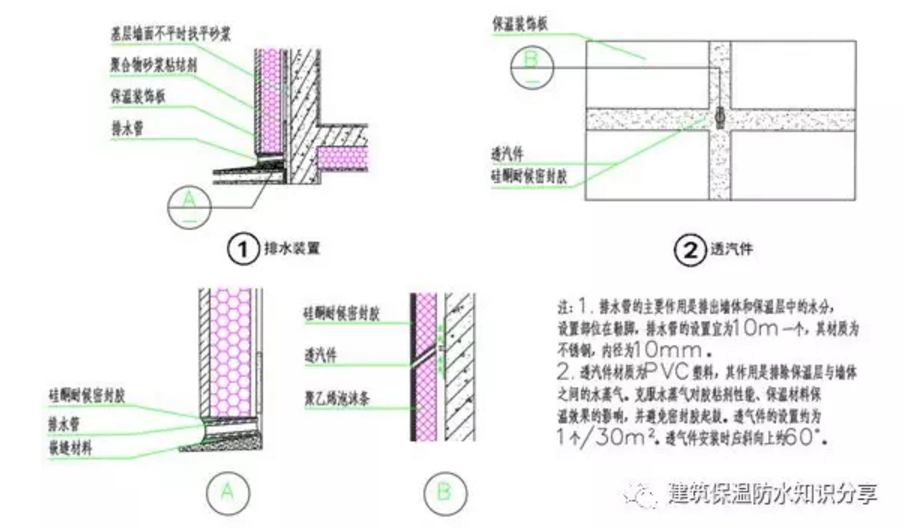

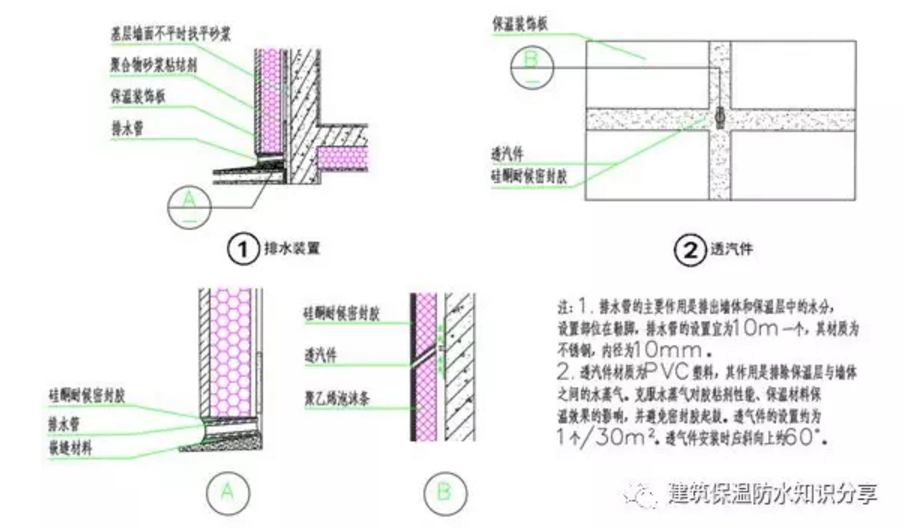

9. Nodes of drainage device and steam permeable parts

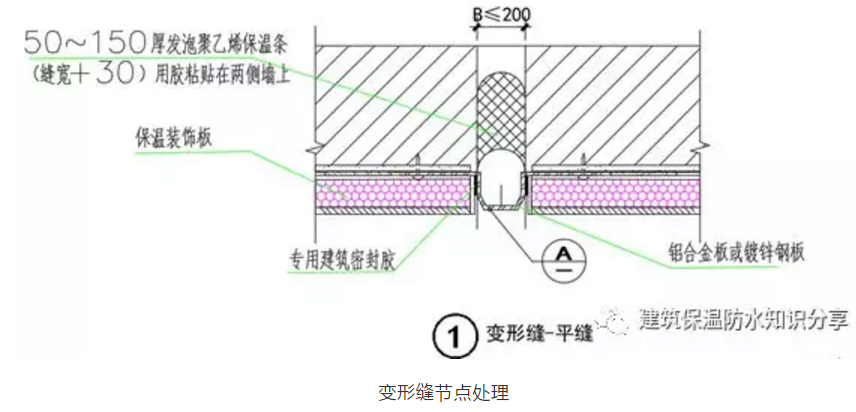

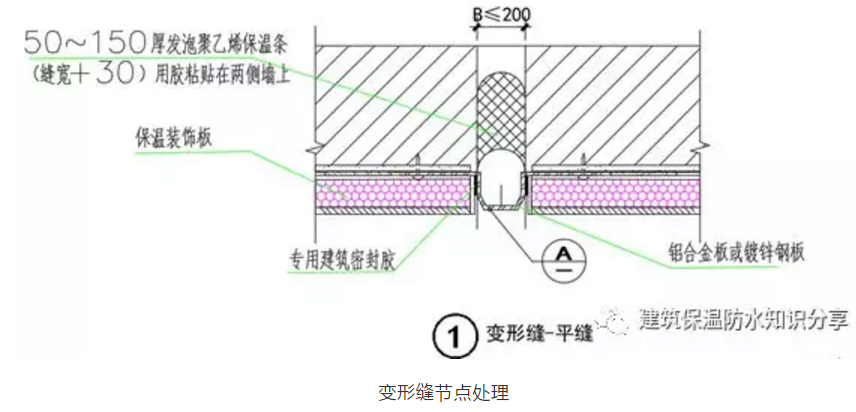

10. Nodes at deformation joints

(1) The thermal insulation decorative plate system shall be disconnected at the deformation joint, and the fastener of the deformation joint cover plate shall be staggered from the anchor of the thermal insulation decorative plate;

(2) The bonding area ratio of thermal insulation decorative board at deformation joint shall be increased appropriately;

(3) The thermal insulation decorative plate shall be fixed up and down, and the distance between the anchor and the deformation joint shall not be more than 200mm. The anchor on other sides of the thermal insulation decorative plate shall be set according to the situation;

(4) The deformation joint shall be filled according to relevant specifications, and the gap between the thermal insulation decorative plate and the deformation joint shall be sealed and filled with sealant.

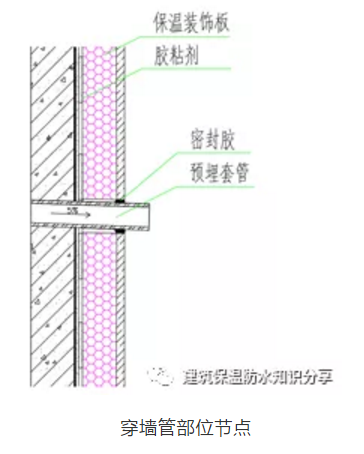

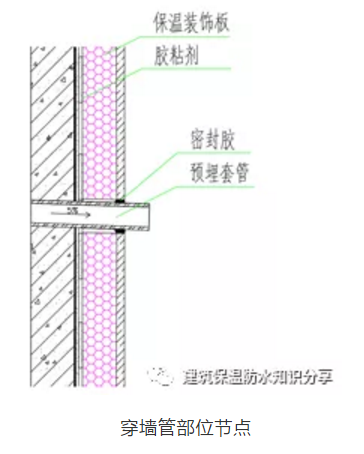

11. Nodes of through wall pipes

(1) The thermal insulation decorative plate shall be cut according to the size of the embedded casing, the opening shall not be too large, and shall be installed according to the construction method of the wall thermal insulation decorative plate;

(2) The thermal insulation decorative plate around the embedded casing shall be pasted tightly;

(3) The gap between the periphery of the embedded sleeve and the insulation decorative plate shall be sealed and filled with sealant.

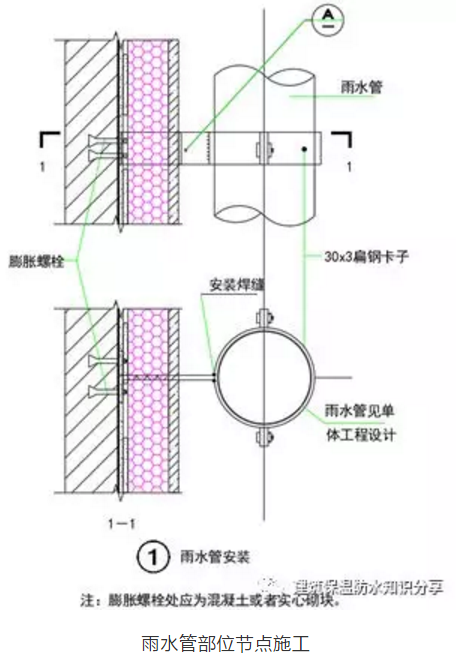

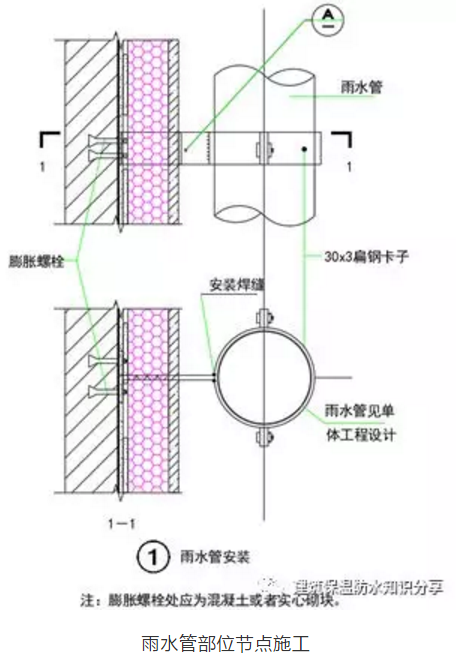

12. Node of rainwater pipe

(1) The thermal insulation decorative plate shall be cut according to the size of the rainwater pipe anchor bolt, and the opening shall not be too large. It shall be installed according to the construction method of the wall thermal insulation decorative plate;

(2) The thermal insulation decorative plate around the pre installed anchor bolt shall be firmly bonded, and the post installed anchor bolt shall be perforated at the firmly bonded part of the thermal insulation decorative plate;

(3) The gap between the anchor bolt periphery and the insulation decorative plate shall be sealed and filled with sealant;

(4) The deformation joint shall be filled according to relevant specifications, and the gap between the thermal insulation decorative plate and the deformation joint shall be sealed and filled with sealant

Note: The content and node diagram of this article are all from the specifications and atlas